Výrobci, ktorí ponúkajú lietané acrylové pláty, vyrobujú pevné, krystalicky čisté pláty, ktoré slúžia rôznorodým účelom. Dozviete sa, o akýchto výrobcovoch ide, a pochopíte, ako sú skutočne zásadní v našich každodenných životoch. Tento článok obsahuje výhody lietaných acrylových plátov, ako aj to, na čo treba dať pozor pri výbere výrobcu, a prečo sa tieto stávajú čoraz bežnejšie v mnohých odvetviach. prísmykovej akrylový plavecký bazén

Použitie výrobcov lisovaných akrylových plátov je vynikajúci nápad, keď potrebujete pláty, ktoré sú nie len prозrážne, ale aj pevné. Tieto aktualizované pláty sú veľmi užitočné a môžu sa používať z mnohých dôvodov. Napríklad sa používajú na výrobu značiek, ktoré sú viditeľné z diaľky, ako aj na okná, ktoré do miestnosti nechávajú vstupovať svetlo a chránia pred počasím. Sú dokonca populárne aj ako akvária, v ktorých môžete pozerať na krásny svet pod vodou. cena akrylového plaveckého bazénu

Ak chcete najlepších výrobcov lisovaných akrylových plátov, uistite sa, že vyberiete toho, ktorý používa kvalitné materiály a berie kvalitu vážne. Týmto spôsobom môžu zabezpečiť, že ich pláty sú trvanlivé, prозrážne a nebudenú sa stávať kruchými alebo lámať. Je tiež dobré nájsť výrobcov s veľmi vysokou úrovňou spokojnosti zákazníkov. Takže ak máte akékoľvek otázky alebo potrebujete pomoc, môžu poskytnúť služby 24 hodín dennovo. Dobre komunikácia so výrobcou zmení vaše zážitky a zaručí, že ste získali presne to, čo potrebujete. akrylová stena bazéna

Je tak dôležité uistiť sa, že najmete presneho výrobcu pre podnikanie, ktoré vyžaduje lišty z odlitného acrylu. Pre dosiahnutie tohto cieľa by ste mali nájsť výrobca, ktorý má skúsenosti s druhom listu, ktorý potrebujete, a dokáže ho vyrobiť v jednej veľkosti alebo farebnej škále, podľa toho, čo odzvie vaše požiadavky. Je tiež rovnako dôležité, aby ste si overili ceny, ktoré účtujú, aby boli v súlade s vaším rozpočtom. Okrem toho skontrolujte ich dodaciu dobu, pretože nechcete mať svoje listy doručené v okamihu, keď už nie sú použiteľné. Dôveryhodný výrobca bude spolupracovať s vami na splnení vašich požiadaviek a uisti sa, že váš podnik bude úspešný.

Podobne ako v prípade iných alternatív, budúcnosť výroby lietaných acrylových plátov je veľmi sľubná a naštastie jasné. S pokrokom technológií teraz ponúkajú výrobci pláty, ktoré sú oboje silnejšie a čistejšie ako kedykoľvek predtým. Dokážu tiež vyrábajať pláty v širšom spektre farieb a rozmerov.

Spoločnosť Lanhu dokáže poskytnúť komplexné riešenie vrátane návrhu akvária, dodávky liatych akrylových dosiek od výrobcov a zariadení LSS, ako aj montáže a uvádzania do prevádzky priamo na mieste. Máme dizajnérsky tím, ktorý môže ponúknuť vývoj, plánovanie a koncepty pre stavbu verejných akvárií. Náš závod vyrába hrubé akrylové panely (40–800 mm) pre okná a tunely v oceánáriách. Dokážeme navrhnúť systémy na podporu života pre veľké akváriá a poskytnúť príslušné zariadenia za konkurencieschopné ceny. V prípade potreby naši odborníci môžu vykonať montáž priamo na mieste po celom svete.

Farba vonkajších proti-UV panelov sa môže trochu zmeniť, ale po 30 rokoch nezazlátne. Naše akrílové panely sú v súlade s príslušnými štátne a odvetvovými štandardmi. Ponúkame 30-ročnú záruku na zmenu farby akrílových panelov. Zabezpečujeme, že za času platnosti záruky sa farba našich akrílových panelov minimálne zmení a nebude dojde k viditeľnému žltaniu alebo zamlhaniu.

Náš tím sa skladá zo skúsenosťami s viac než 20 rokmi priemyselnej praxe a vieme rýchlo reagovať na požiadavky zákazníkov ako výrobcovia liatych akrylových dosiek. Náš predajný tím má vynikajúcu komunikáciu s koncovými užívateľmi alebo dodávateľmi, zatiaľ čo naše dizajnové tímy dokážu rýchlo pripraviť návrhy. Ak máte naliehavý projekt, vieme sa prispôsobiť v riadení a dodávať včas. Vďaka našim rozsiahlenym skúsenostiam vždy vieme pomôcť klientovi nájsť najlepšie riešenie.

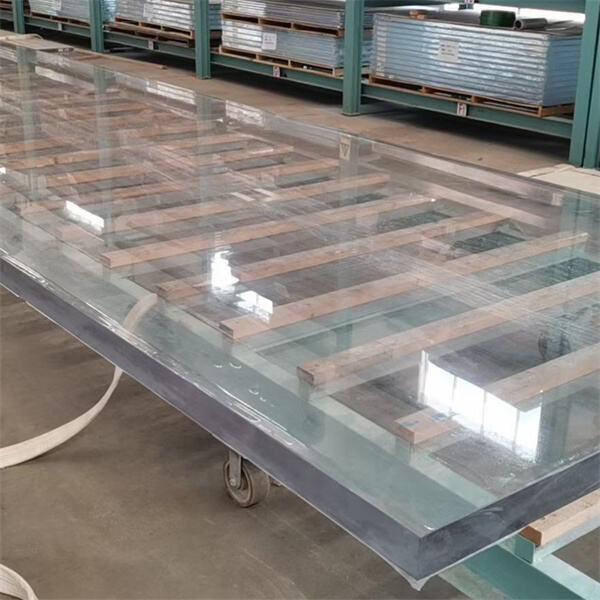

Výrobcovia liatych akrylových dosiek majú priepustnosť vyššiu ako 93 %. Čistota MMA 100 % sa dovozí priamo z firmy Mitsubishi Lucite. CNC režanie zabezpečuje presnejšie rozmery. Každá doska má hladký a dokonale leštený povrch. Vyššia pevnosť švíkov (ak sú prítomné): po spojení sa dosky žiarovo spracujú, čo vedie k vyššej pevnosti a estetike. Vnútorné napätie v tepelne spracovaných akrylových doskách sa odstráni žiarovým spracovaním. Pred zabalením každej dosky vykonávame dôkladnú kontrolu za osvetlenia. Aby sme prekročili očakávania zákazníkov, venujeme osobitnú pozornosť každému detailu výrobného procesu.