Kāpēc akriļa ir labs materiāls jūsu DIY projektos. Tas ir veids no plastmasas, ko var formas un krāsot dažādos veidos. Ar to jūs varat izveidot gandrīz jebko – skaistu rāmi, kādu modēru piederumu vai pat fantāzijas tortu virsoli šai īpašajai dienai. Ja plānojat veikt daudz projektu ar akriļu, es iesaku iegādāties Formēto Akriļa Lāpi. Šajā rakstā jūs uzzināsiet visu, kas jums nepieciešams par formēto akriļa lapiem un kāpēc tie ir tik piemēroti tam, kas prasa.

Vēl fantastiskāk par to, kas attiecas uz izgrieztajiem akriļa plāksnēm, ir tas, ka tās ir ļoti caurspīdīgas. Kad tās tiek grieztas un politas, tās spīd kā stikls! Bet patiesi interesanti ir tas, ka tās ir ļoti stipras; vairāk nekā parastais stikls. Tās ir ideālas, jo ar tām var izgatavot attēlu rāmi vai kastes un citas līdzīgas lietas, jo tām ir skaidrs vizuālais sistēmas. Turklāt, izgrieztās akriļa plāksnes ir arī ļoti viegli apstrādājamas. Tās var griezt ar šķēdi vai laserskaņu un jālieto speciāla akriļa lipītājs, jo tas izgatavots no šā materiāla. Tās ir arī diezgan vieglas, un tāpēc tos ir viegli pārvietot no vienas vietas uz otru, strādājot pie savām projektēm.

Formētie akriļa lapas ir tik populāras starp dizaineriem un veidotājiem, jo tās ļauj realizēt plašu iespēju spektru, izstrādājot produktus no šī brīnišķīgā materiāla. Ar tām var izveidot zīmes vai arī spēles, kurās bērni spēlē un interaktīvi sadarbojas, izmantojot savu fantāziju vairāk parasti nekā tikai atvieglotā brīvā spēlē, bet arī kā medicīnas rīkus, ko ārsti izmanto, lai glābtu dzīvības. Ir pieejamas daudzas spilgtas krāsu varianti, kas der jūsu projektam. Spēks un ilgtspēja ir vienas no iemesliem, kāpēc dizaineri nevar pietikt no formētajām akriļa lapām. Tās nesatrūkst kā stikls, kas tos padara daudz mazāk bīstamiem daudzās lietojumprogrammās. Tas nozīmē, ka jūs varat to iekļaut savos projektos un aizmirst par fragmentiem.

Iegādājoties formētu akriļa plāksni, ir daži aspekti, uz kuriem vajadzētu pievērst uzmanību. Tip #1: Pirmkārt, pārliecinieties, vai izmantojat pareizo plāksnes biežumu savam projektam. Karsts tips Nr. 2 - Kāda veida? Biežākas metāla plāksnes nozīmē lielāku stiprumu, bet tās padara jums grūtāk darboties ar tām, jo... (ja plāksnes svars var būt jautājums) Biežākas plāksnes ir stiprākas nekā tumšākas, bet vieglākas un vieglāk apstrādāmas. Turklāt jums būs jāizvēlas arī plāksnes izmērs. Ja strādājat pie liela projekta (ar koka zīmoliem vai ko lielāku par šo zīmolu izmēru, pārliecinieties, ka ir pieejama liela akriļa plāksne). Visbeidzot, ņemiet vērā, kādu krāsu vēlaties. Abiem tipiem: Vai jums vajadzīga caura, ar caurumu kāda ar citu vai jums nepieciešamas spožas krāsas, kas viegli var tikt redzamas?

Tas, kas padara izgrieztos akriļa plāksnes tik unikālām, ir tas, ka tās var tikt izmantotas visam. Biežākā lietojuma piemērs ir reklāmas zīmes. Droši var teikt, ka jūs esat ievērojis daudz šādu zīmju, kas veidotas no caurā akriļa ar burtiem vai attēliem uz tām. Kredīts: TechCrunch Tās tiešām izskatās skaisti un ļoti lasāmi! No šīs attēlojumā redzami detaļas skaidri un precīzi. Izgrieztās akriļa plāksnes tiek arī izmantotas medicīnas rīku ražošanā, jo tās var tikt noglabātas, lai novērstu infekciju. Tās tiek arī bieži izmantotas stipru spēļu ražošanā, ar kurām bērni spēlējas ilgi. Tas ir tas, kas padara izgrieztās akriļa plāksnes tik briljantām!

Un šeit ir daži padomi, kuru jums vajadzētu ņemt vērā, kad lietojat gredzenveida akriļa plāksnes kā materiālu DIY projektos! Pirms sākat darbu, pārliecinieties, ka ir pieejamas noteiktas rīkas. Akriļa: Sērijas vai laserskaņējs, lai grieztu akriļu vēlamo formu. Turklāt jums būs nepieciešams speciāls lipnis, lai saistītu daļiņas pareizi. Darbs ar gredzenveida akriļa plāksnēm Patiesībā nevērojiet to, ja strādājat pie projekta, izmantojot grieztu līdz izmēram caurā plastmasu, jo tā var sprāgt. Atcerieties vienmēr aizsargāt roku, uzliecot guantes, un to pašu darīt acīm - drošība pirmais, kad strādājat.

Ārējo anti-UV akriļa panelu krāsas viegli mainās ar laiku, bet pēc 30 gadiem nav izbīdējuma. Mūsu akriļa paneļi atbilst nozaru standartiem un valsts standartiem. Mēs piedāvājam 30 gadus ilgu garantiju pret akriļa panelu krāsu maiņām. Garantējam, ka akriļa panelu krāsas neizmainīsies nozīmīgi garantijas laikā un nebūs redzami žogas dzeltēšanas vai krāsu maiņas pazīmes.

Mūsu komandai ir vairāk nekā 20 gadu pieredze rūpniecībā, iegādājoties liešanas akrila plāksnes, un mēs varam ātri reaģēt uz klientu pieprasījumiem. Neatkarīgi no tā, vai jūs esat profesionāls uzņēmējs vai galalietotājs, mūsu pārdošanas pārstāvji vienmēr uzturēs ar jums saziņu, bet mūsu dizaina komandas dalībnieki var ātri izstrādāt shēmas projektu rasējumus. Mēs darīsim visu iespējamo, lai pārvaldītu steidzamus projektus un nodrošinātu to pabeigšanu laikā.

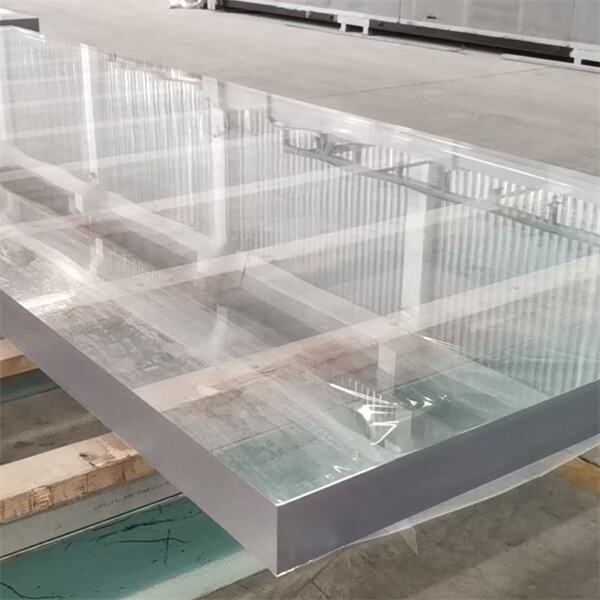

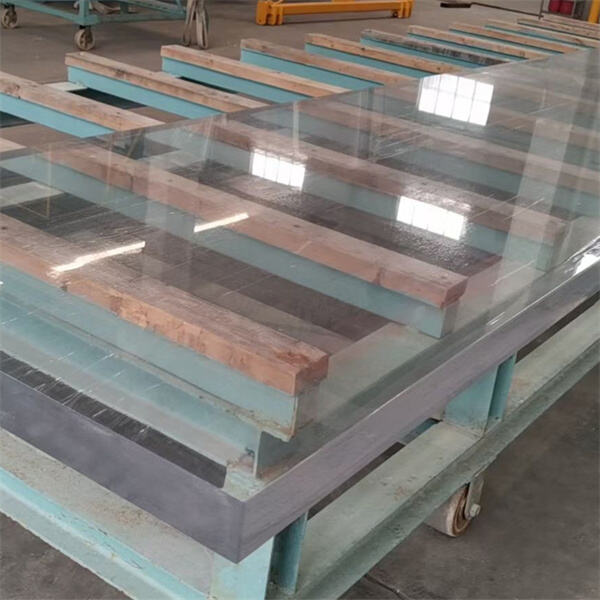

Akrila panelu caurspīdīgums ir vairāk nekā 93 %. 100 % tīrības MMA tiek importēts tieši no Mitsubishi Lucite. Iegādājoties liektā akrila loksnes, iegūst precīzākus izmērus. Katrs panels ir perfekti polirēts ar gludu virsmu. Ja nepieciešams, pēc savienošanas panāk lielāku šuvju izturību. Savienoto panelu termiskā apstrāde (atkausēšana) uzlabo to izturību un estētisko izskatu. Atkausēšana noņem akrila panelos iekšējo saspīlējumu, kas rodas, to termiski apstrādājot krāsnī. Pirms iepakošanas katru paneli pārbaudām ar gaismas avotu. Mēs esam uzmanīgi pret katru sīkumu ražošanā, lai varētu atbilst klientu sagaidījumiem.

Lanhu piedāvā komplektu pakalpojumu, kas ietver akvāriju projektēšanu, akriliskā materiāla izgatavošanu, LSS aprīkojumu, uzstādīšanu un akrilisko loksnes pirkšanu. Mums ir projektēšanas komanda, kas var nodrošināt sabiedrisko akvāriju plānošanu, izstrādi un būvniecībai paredzētu projektēšanu. Mūsu rūpnīca ražo biezas akriliskās plates (40–800 mm) logiem okeānārijos un tuneliem. Mēs arī varam izstrādāt dzīvības uzturēšanas sistēmu lieliem akvārijiem un piegādāt aprīkojumu konkurences spējīgā cenā. Ja nepieciešams, mūsu tehniskie speciālisti var veikt akvārija uzstādīšanu vietā visā pasaulē.