Τι είναι τα φύλλα ακρυλικού (φύλλα PMMA); Με την ευρεία γama πλεονεκτημάτων και εφαρμογών, αυτά τα φύλλα είναι ένα απαραίτητο υλικό σε διάφορους τομείς.

Τα φύλλα ακρυλικού είναι ιδεαλιστικά, καθώς προσφέρουν μια σειρά χαρακτηριστικών, συμπεριλαμβανομένης της μικρότερης βάρυτας και της ικανότητας να μην κατασπαστούν σε σύγκριση με το παραδοσιακό γυαλί. Επιπλέον, είναι ένα σύνολο φύλλων που προσφέρει το καλύτερο σε υψηλή απόδοση και βιωσιμότητα. Δεν μπαφτίζονται με την πάροδο του χρόνου και είναι επίσης ευκολότερα να καθαριστούν και να διατηρηθούν σε σχέση με το τυπικό γυαλί. Επιπλέον, διατίθενται σε διάφορες χρωματικές τονες, ολισθήματα και μεγέθη για να καλύψουν όλες τις διαφορετικές ανάγκες σας.

Αυτό έχει γίνει δυνατό εξαιτίας της συνεχούς εξέλιξης στον τομέα και με κάθε νέα ανάπτυξη, τα φύλλα ακρυλικού προωθούνται προς έναν παράμετρο που υπηρετεί διαφορετικούς τομείς σύμφωνα. Ένα παράδειγμα αυτού είναι η αντοχή τους σε κύμανση, η αντοχή τους στην UV ακτινοβολία και η βαθμολογία τους για πυρκαγιά που συνεχίζουν να βελτιώνονται όπως εισαγόνται νέα προσθέτα. Οι εξελίξεις στην τεχνολογία έχουν παράγει επίσης υλικά όπως ακρυλικά με μοναδικές υφές, μοτίβα και αισθητικά ποιότητες, επιτρέποντας στους αρχιτέκτονες και σχεδιαστές να επεκτείνουν τα διαφορετικά κρεατιβά όρια των κατασκευών τους.

Τα κορυφαία αρθρά σχετικά με τα φύλλα ακρυλικού: Πώς να χρησιμοποιήσετε ένα φύλλο ακρυλικού με ασφάλεια, Πρωταθλητής παραγωγός φύλλων πολυκαρβονάτου και ακρυλικού. Πρέπει να είναι προσεκτικοί κατά την χειρισμή τους, και όταν κάνουν εντομώσεις, μπορεί να χρειαστεί να χρησιμοποιήσουν δεξαμενά, μάτια και μάscaras. Είναι κρίσιμο να αποθηκεύεται ένα φύλλο σε τις σωστές συνθήκες (ψύχρα, ξερά) όπου δεν θα καμπύλωνται ή θα καταστραφούν με τον χρόνο, βάζοντάς το έτσι εκτός λειτουργίας.

Τα φύλλα ακρυλικού εμπλέκονται σε διάφορες εφαρμογές σε πολλές βιομηχανίες, όπως η κατασκευή, η αυτοκινητοβιομηχανία, η ιατρική και ο τομέας της προσωπικής. Επιπλέον, οι εφαρμογές περιλαμβάνουν παράθυρα, ανοιχτά φωτιστικά, διαφορικά, σημειώσεις & μπερντ, πακέτα και εμφανίσεις, προστατευτικά φραγματά, γυαλιστικά/φωνικά φραγματά/διαχειριστές φωτισμού κλπ. Το όριο της χρήσης τους είναι απλώς η φαντασία σας - με απεριόριστες δυνατότητες χρήσης για επιδιώξεις φαντασίας.

Χρειάζεστε να έχετε τα σωστά εργαλεία και τεχνικές για να χρησιμοποιήσετε τα πλαστικά φύλλα με τον κατάλληλο τρόπο. Κατά την κοπή ή το μποράρι αυτών των φύλλων, είναι σύμβουλο να χρησιμοποιήσετε ένα ειδικό δεξαμενόπλαστο που σχεδιάστηκε για πλαστικά, ενώ δεν παρέχει πολύ φρικτιον στην επιφάνεια του φύλλου σας, διαφορετικά μπορεί να το βλάψετε. Μπορείτε να χρησιμοποιήσετε ένα μηχανήμα θερμαντικής αεροσόδου ή καμπαρίσας για να μοντελώσετε τα πλαστικά φύλλα σε καμπά, σχήματα κλπ. Καθαρίστε με μαλακό σαπόνι και μαλακό χούρτι. Αποφεύγετε τη χρήση αφροϊστικών ή οξικών καθαριστικών. Μπορείτε να διατηρήσετε τη λάμψη και την διαφάνεια τους με τη χρήση μιας μπριλιάνσας για πλαστικά ή μιας μπριλιάνσας-κηλίδας.

Όταν πρόκειται για το σωστό μέρος στο Ντένβερ για να αγοράσετε αυτά τα φύλλα ακρυλικού, είναι πολύ σημαντικό να έχετε έναν προμηθευτή που μπορεί να προσφέρει προσωπική φροντίδα και προσοχή, παράδοση στον χρόνο ή ακόμη και να έχει διαθέσιμα ό,τι χρειάζεστε σε κάθε περίπτωση. Αναζητήστε έναν προμηθευτή που μπορεί να καλύψει τις ανάγκες σας, προσφέρει λύσεις τμήματος και μεγεθών κατά τάξη καθώς και ειδική τεχνική βοήθεια. Βεβαιωθείτε ότι ο πωλητής έχει καλή φήμη, υπηρεσίες όπως εγγύηση και επιστροφή θα βοηθήσουν σε περίπτωση που δεν είστε ικανοποιημένοι με την αγορά σας.

Η χρωματικότητα των εξωτερικών φυλλών με αντι-UV θα αλλάξει ελαφρώς, ωστόσο δεν θα ξανθεύσουν μετά από 30 χρόνια. Τα φύλλα ακρυλικού που παρέχουμε είναι σύμφωνα με τις σχετικές προδιαγραφές της χώρας και των βιομηχανικών προδιαγραφών. Προσφέρουμε εγγύηση 30 ετών για την αλλαγή χρώματος των φυλλών ακρυλικού. Δεσμευόμαστε ότι η χρωματικότητα των φυλλών ακρυλικού μας θα αλλάξει λίγο κατά τη διάρκεια της περιόδου εγγύησης και δεν θα υπάρξει έντονη ξανθώση ή διαφάνεια.

Η ομάδα μας διαθέτει περισσότερο από 20 χρόνια εμπειρίας στον κλάδο και είναι σε θέση να ανταποκρίνεται άμεσα στις ανάγκες των πελατών. Η ομάδα πωλήσεών μας επικοινωνεί αποτελεσματικά με χρήστες ή εργολήπτες, ενώ οι μηχανικοί μας μπορούν να παρέχουν γρήγορα σχέδια για μεγάλα ακρυλικά φύλλα. Για επείγοντα έργα, είμαστε εύκαμπτοι στον έλεγχο και την ταχεία παράδοση. Με την εμπειρία και γνώση που διαθέτουμε, μπορούμε να βοηθήσουμε τους πελάτες να βρουν την καλύτερη δυνατή λύση.

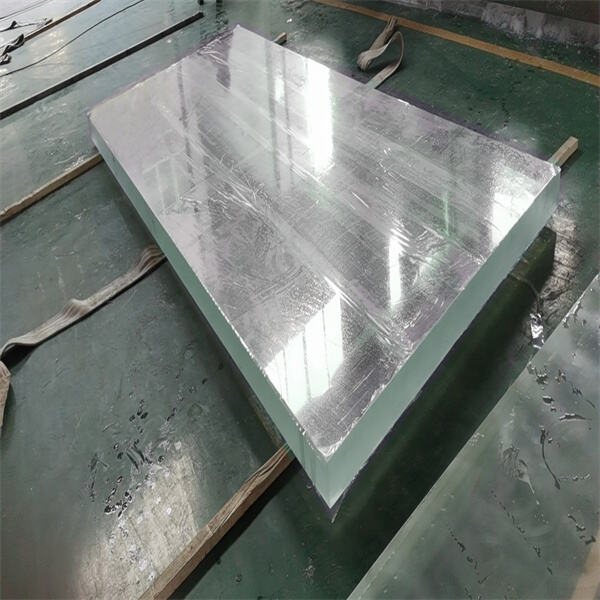

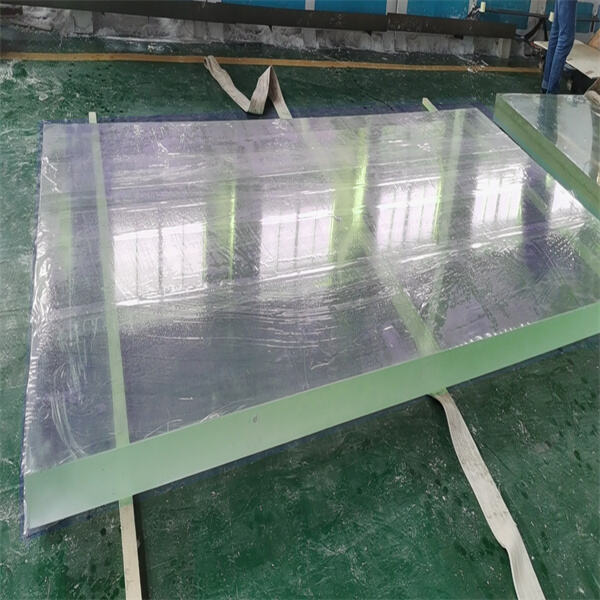

Η διαφάνεια των μεγάλων φύλλων ακρυλικού (ακρυλικών πλακών) υπερβαίνει το 93%. Το μονομερές μεθακρυλικού μεθυλεστέρα (MMA) με καθαρότητα 100% προέρχεται απευθείας από την Mitsubishi Lucite. Η κοπή με CNC εξασφαλίζει ακριβέστερες διαστάσεις. Κάθε πλάκα λαμπρύνεται τέλεια, με ομαλή επιφάνεια. Εάν απαιτείται, για να αυξηθεί η αντοχή των αρμών μετά τη σύνδεση, οι πλάκες υποβάλλονται σε ανόπτηση, προκειμένου να βελτιωθεί η μηχανική τους αντοχή και η αισθητική τους εμφάνιση. Η ανόπτηση απαλείφει τις εντατικές τάσεις που δημιουργούνται στις ακρυλικές πλάκες κατά την επεξεργασία τους και επιτρέπει την ενίσχυσή τους σε φούρνο. Πραγματοποιούμε ενδελεχή έλεγχο κάθε πλάκας υπό φωτισμό πριν από τη συσκευασία. Επιδεικνύουμε προσοχή σε κάθε στάδιο της διαδικασίας παραγωγής, προκειμένου να υπερβούμε τις προσδοκίες των πελατών μας.

Η Lanhu προσφέρει ολοκληρωμένες λύσεις για μεγάλα ακρυλικά φύλλα, αρχίζοντας από το σχεδιασμό ενυδρείων, την κατασκευή ακρυλικού υλικού, την προμήθεια εξοπλισμού LSS, την εγκατάσταση επιτόπου και την παραλαβή. Διαθέτουμε ομάδα σχεδιασμού η οποία μπορεί να προσφέρει σχεδιασμό, ανάπτυξη και μελέτη δημόσιων ενυδρείων για κατασκευή. Το εργοστάσιό μας κατασκευάζει παχιά ακρυλικά πανέλ (40–800 mm) για παράθυρα και σήραγγες θαλασσοθεάτρων. Μπορούμε επίσης να σχεδιάσουμε συστήματα υποστήριξης ζωής για μεγάλα ενυδρεία, καθώς και να προμηθεύσουμε εξοπλισμό σε λογικές τιμές. Οι τεχνικοί μας είναι έτοιμοι να εγκαταστήσουν εξοπλισμό επιτόπου σε οποιοδήποτε σημείο του πλανήτη.