If you need a special material that is clear and shiny, like to make something cool such as birdhouse or picture frame. Enter cast acrylic sheets! They are large, flat pieces of thick plastic that can be cut and molded in a multitude of fashions. They can be very helpful for many projects. So what are the actual prices of these cast acrylic sheets? Here, in this blog post let's discuss it a bit more.

But lets be honest about a few points first before we get into the prices that can affect how much you have to pay for your cast acrylic sheet. Real Eye Size: one of the most obvious reasons is approximately a whole sheet. Is it small like a picture frame, or larger as if you were peering through your window? Larger sheets are more expensive as they consume larger amount of material during manufacture. The thickness of the sheet should also be noticed. Thicker sheets are stronger and live longer, but they also tend to be more costly. And finally, a few might have other characteristics (i. e. being immune to UV light exposure so they never discolor or be resistant to scrape and stay shinning). There are a limit and downside to these features, with things that will both make the sheets more expensive.

With all of the factors that go into play in deciding cast acrylic sheet price, you're probably wondering if there are any cost-effective options. Good news: YES, cheap cast acrylic sheets are available! Some 1/8 inch or less, smaller sheets may be as low as $5 or $6. For quick little things, they are great. The larger sheets, 1/4 inch or thicker start to get more expensive but you should be able to find some nice ones for under $50. This means that regardless of your budget, you can likely find at least one cast acrylic sheet available to suit it!

You must keep in mind that not all Cast Acrylic sheets are created equally. Regarding the more expensive sets, some sheets are higher quality and production costs as such can be a little bit pricier. To give you an indication, here is a rough guideline to price ranges —

All cast acrylic sheets are not created equal as we discussed earlier. Others could be less expensive for a reason, being I'm built cheaply or processed. However, does that mean you should always pick the most expensive sheets? Not necessarily! You want to make sure you are getting good value for money. Important Considerations when reviewing different materials for cast acrylic sheets;

Lastly, we will discuss why cast acrylic sheet prices can vary so much on a per-sheet basis. The manufacture of cast acrylic sheets is alike to DJI MAKROLON, in that liquid acrilay a solutionable precursorsta are poured into molds and heated then allowed cool to form solid plastic shets. Factors that might alter the price are:

Acrylite (Germany): Acrylite is known for making the finest subtly cast acrylics in existence and their white sheet goods are near-indestructible. Their sheets do come with a high price tag-count on spending over $50 for just one sheet-but the quality truly is unmatched.

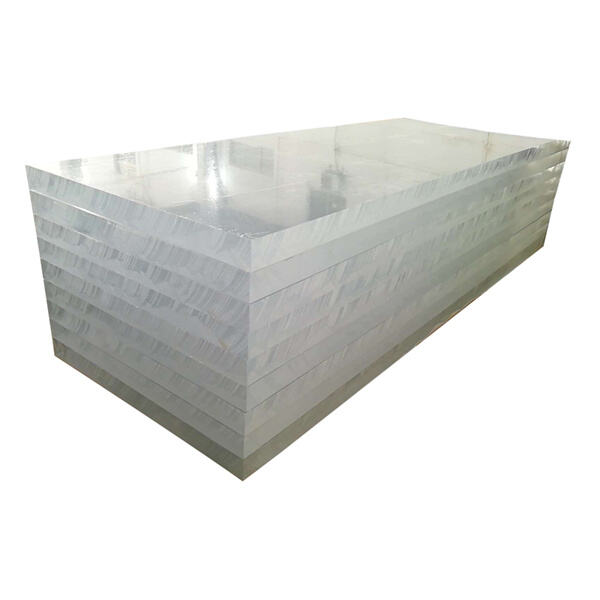

Lanhu provides a complete solution which includes Cast acrylic sheet price fabrication of acrylic material, LSS equipment, installation and commissioning. We have a design group which can offer public aquarium development, planning, as well as construction designs. Our factory produces thick acrylic panels(40-800mm) for oceanarium windows and tunnels. We can also design a life support systems for large aquariums and provide equipment at an affordable price. If necessary, our experts can install on-site across the globe.

100% pure MMA Imported from Mitsubishi Lucite, acrylic panel transmittance of more than 93 percent. CNC cutting brings more precise dimensions. Each panel features a perfect, smooth surface. More seam strength (if there is any) After splicing, the panel is annealed to give better strength and aesthetics. Annealing removes stress of acrylic panels tempered in oven. We conduct a thorough inspections under lights for each panel before packing. To exceed the Cast acrylic sheet price expectations We pay close attention to every aspect of the manufacturing process.

Our team is comprised of more than 20 years of industrial experience and can Cast acrylic sheet price quickly to customer requests. Our sales team has excellent communication with the end user or contractors, while our design teams can rapidly draw up schemes. If you have a project that is urgent We do to be flexible in management and timely delivery. With extensive experience, we can always guide the client to find the best solution.

Outdoor anti-UV acrylic panel colors change slightly with age but not fading after 30 years Our acrylic panels are in compliance with industry standards as well as country standards We offer a 30-year guarantee on changes in color of acrylic panels We guarantee that the colors of acrylic panels won't change significantly during the warranty time and that there aren't any visible signs of yellowing or discoloration