What are the Acrylic Sheets (PMMA sheets)? With the wide range of benefits and application, these sheets are a must-have material in various industries.

Acrylic sheets are ideal as they bring a variety of features including its lighter weight and shatter-resistant property compared to traditional glass. Moreover, it is a set of sheets that provides the very best in high performance durability and flex life. Not only do acrylic sheets not yellow over time, it is also easier to clean and maintain than typical glass. Plus, they come in various colors and finishes and sizes for all of your different needs.

This has been possible because of the constant evolution in the space and with every new development, acrylic sheets are pushed towards a parameter that serves different industries accordingly. An example of this is their impact strength, UV resistance and fire rating continuing to improve as new additives are introduced. Advancements in technology have also produced materials such as acrylics with unique textures, patterns and optical qualities enabling architects and designers to extend the creative boundaries of their constructionings.

Top posts related to acrylic sheets How to use an Acrylic Sheet Safely Premium Producer Of Polycarbonate And Acrylic Sheets. They must be careful handling them, and when making cuts drills or milditions must use gloves, goggles and masks. It is critical that a board be stored in the proper conditions (cool, dry) where they will not warp or get mashed up over time thus putting it out of commission.

Acrylic sheets are involved in various applications across several industries such as construction, automotive industry, medical field and the retail sector. Further, the applications include windows, skylights, partitions; signage & awnings; packaging and displays protective barriers, glazing/sound barriers/lighting diffusers etc. The limit to their utility is merely your imagination - with endless potential uses for imaginative innovation.

You need have the right tools and techniques to use acrylic sheets appropriately. In cutting or drilling these sheets, it is advisable to apply a specialized saw blade designed for plastics while not providing much friction on the surface of your sheet otherwise you may end up damaging it. You can use a heat gun or bending machine to mold the acrylic sheets into curves, shapes etc. Clean with a mild soap and soft rag; avoid using abrasive or acidic cleaners You can further retain their brilliance and clarity by using a plastic polish or polishing wax.

When it comes to the right place in Denver for you to purchase these acrylic sheets, having a supplier that can provide personal care and attention, delivery on time or better yet if they carry what you need at all times is very important. Look for a supplier who can accommodate your needs, offers custom cutting and sizing solutions as well specialist technical help. Make sure that the seller has a good reputation, services like warranty and return would help in case you are not satisficed with your purchase.

Color of outdoor anti-UV panels will alter slightly however they won't turn yellow after 30 years The acrylic panels we provide are in line with the relevant standards for the country and the industry standards We offer a 30-year guarantee on acrylic panel color changing We promise the color of our acrylic panels will change little during the warranty time and there will not be obvious yellowing or turbidity

Our team has more than 20 years of experience in the industry and is able to respond promptly to the needs of clients. Our sales team has great communication with users or contractors, while our design teams can swiftly provide drawings for Big acrylic sheet. For urgent project we do to be flexible in control and speedy delivery. With extensive experience and knowledge, we are able to provide the client to find the best solution.

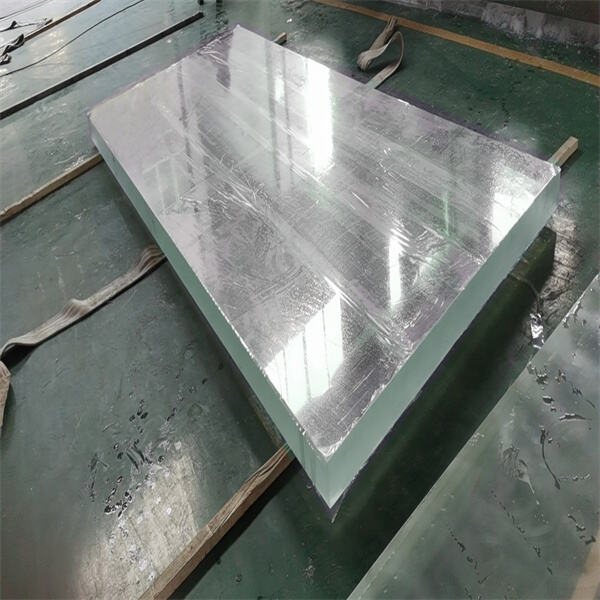

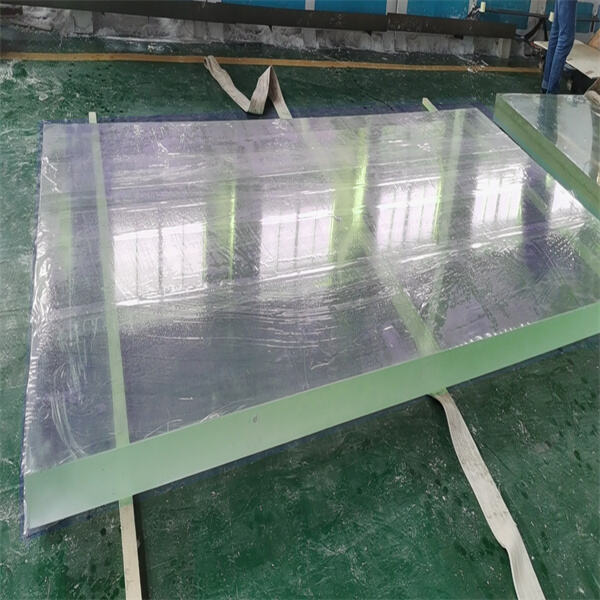

Big acrylic sheet of acrylic panels is more than 93 percent. 100% purity MMA obtained directly from Mitsubishi Lucite. CNC cutting brings more precise dimensions. Each panel is perfectly polished with a smooth surface. If needed, stronger the strength of seams After splicing, the panels are annealed for better strength and aesthetics. Annealing removes stress on acrylic panels when they are and can be tempered in oven. We perform a rigorous check under lighting for each panel prior to packing. We pay attention to every aspect throughout the process of manufacturing to exceed the customer's expectations.

Lanhu offers turnkey Big acrylic sheet starting with aquariums design, acrylic material fabrication, LSS equipment supply, onsite installation and commissioning. We have a design group which can offer public aquarium planning, development and design for construction. Our factory manufactures thick acrylic panels(40-800mm) for oceanarium windows and tunnels. We can also design a life support systems for large aquariums as well as supply equipment at a reasonable price. Our technicians are ready to set up equipment on-site anyplace around the globe.