You are here: Home > Acrylic Sheet Large - A Drilling Fluid and Pumping Solution All In [email protected](Text_Head.getKeyTextSize())Acrylic Sheet Large - A Drilling Fluid and Pumping Solution All In Onet.By Anam Iqbal | Submitted On September 10, [CONTINUE READING]

Acrylic sheet large is so versatile in nature and can be used for a countless number of projects because of its great properties. This is a go-to material used everywhere from elementary school science projects to middle-school marketing campaigns. Today, we will explore the wide range of benefits and unique features as well associated with acrylic sheet large along with few safety pointsConsumption guidelinesQuality detailsVarious strategiesPurpose-based applications

Contains Benefits Of Acrylic Sheet Large

Large sheet size acrylic is simply a best material choice as it offers so many advantages over most of its alternatives. Besides it is light in weight, nonshatterable also easily manipulates by cutting drilling or molding. Its weather resistance, UV stability and long-time transparency make it different from other materials. The high light transmittance of the material, which far exceeds that of glass, ensures that it is a suitable alternative for different presentations. Also, because it is recyclable loliplast acrylglas win due to fascinating in an eco data.

Contemporary acrylic Sheet big have been improved over time, allowing for the creation of new formulations with added qualities. That effort has led to advancements in resilience against bullets and severe weather. In addition, the material is available in a wide range of colors, patterns and textures that further expand its potential for decorative as well as branding details.

Why Acrylic Sheet Large But Rigid And Hollow Safe

Safety - One of the most significant features which makes acrylic sheet large a paramount choice over others. It is not likely to break, unlike glass, which can prevent a serious sports injury. This quality makes it an ideal choice for impact-disposed applications like so little of aquariums and signage. It is also highly UV and chemically resistant, making it ideal for hazardous area locations.

Acrylic Sheet Large needs to be handled with care and the correct methods need to be used during work. Using the right tools is crucial to avoid damage during cutting. Handheld cutters or saws with fine tooth blades, are appropriateor laser,CNCHttpServletRequests. Safety precautions must be taken-Have you ever worked with acrylic sheet large before?, If not, then safety precautions are the most important thing to consider. Which includes wearing goggles and gloves while working.

The quality of the acrylic sheet joiner can vary depending on many items including but not limited to manufacturer, formulation and processing methods. This is the material that must be acquired from reputable suppliers with product quality standards and service above average. Choose suppliers that offer a variety of grades, thickness levels and even PVC color options as well texture. In addition, knowledgeable staff able to help select materials, customize them and deliver in a timely manner are important factors.

Uses of Acrylic Sheet in Big Form

It is widely used in different types of industries due to the versatility and flexibility that it offers while being lightweight at the same time. It is widely utilized in a building industry for glazing, roofing and cladding applications. Acrylic sheet are large used in the advertising industry to create signs, displays and product stands. It is also great for the production of aquariums, furniture and lighting.

Thus acrylic sheet large is concluded as more advanced material based on many advantages it has over old traditional tenacious. Because of its versatility, durability and easy way to use it is preferred in many industries. Acrylic sheet large is ideal for students on a project or professionals looking to complete their work using quality materials. Wether its innovative properties, safety features, workability, better quality standards or diverse applicability it is an enticing option for all your project needs. So, if you are looking for a material that offers unmatched properties and is versatile as well to be used in your upcoming next project than the large acrylic sheet rushes at no bar.

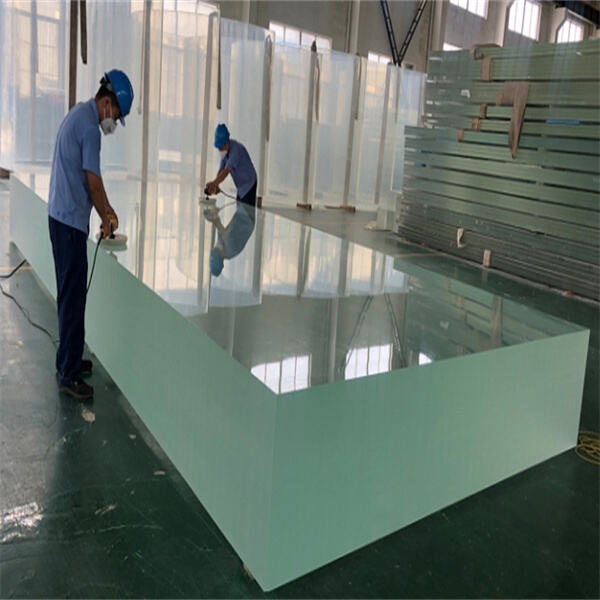

Lanhu offers Acrylic sheet large solutions for aquariums including acrylic material fabrication LSS equipment, onsite installation and commissioning. With our professional design team, we are able to do public aquarium planning design as well as development and construction design. Our factory produces thick acrylic panels (40-800mm) that can be used to construct oceanarium tunnels and windows. We design life-support systems for large aquariums, and supply equipment at competitive cost. Our experts are able to put equipment in place on site anywhere in the world.

Our team has more than 20 years of experience in the industry and is able to respond promptly to the needs of clients. Our sales team has great communication with users or contractors, while our design teams can swiftly provide drawings for Acrylic sheet large. For urgent project we do to be flexible in control and speedy delivery. With extensive experience and knowledge, we are able to provide the client to find the best solution.

Outdoor anti-UV acrylic panel color changes a bit with age but not fading after 30 years Our acrylic panels are compliant with international standards and standards We offer a guarantee of 30 years on color changes in acrylic panels We guarantee that the colors of acrylic panels won't change significantly during the warranty time and that there aren't any visible signs of discoloration or yellowing

Acrylic panels have a transmittance of more than Acrylic sheet large. 100 Pure MMA obtained directly from Mitsubishi Lucite. CNC cutting brings more precise dimensions. Each panel is flawlessly polished and has a smooth surface. If needed, stronger seam strength is achieved After splicing, the panels are annealed for better strength and aesthetics. Annealing can remove internal stress of acrylic panels which are heated in oven. We ensure that we conduct an exact check under lighting for each panel prior to packing. We care about every detail during process of production to meet the client's expectations.