Versatility and Dependability of Acrylic Sheets

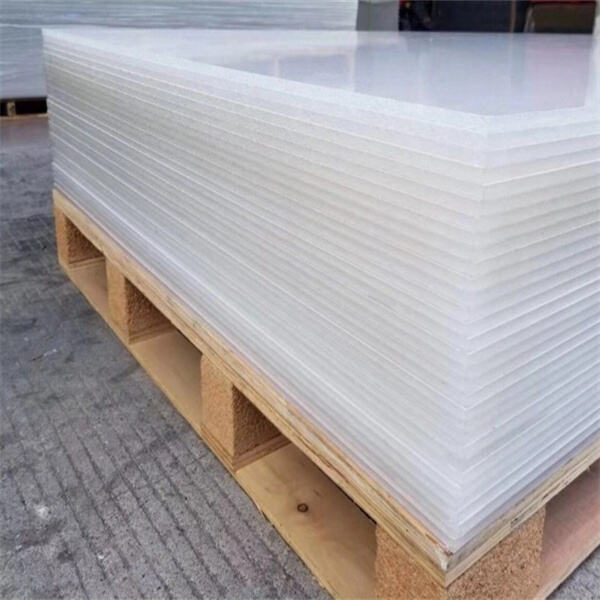

Their unique properties have made acrylic sheets used in more and more places that are imaginable today. Known for their transparency and durability, these sheets remain one of the most widely used materials. Acrylic sheets are made with a very raw and tough material, which can sustain the impact to stop it from flowing; thus able to function as much better glass than usual.

Acrylic Sheets: The Stand Apart Material Being up to 10 times stronger, acrylic sheets are substantially more resistant than glass in most applications. They are perfect to be used in working at height and confined spaces, both of low risk as potentially hazardous environments due their greater resistance. Besides, acrylic sheets are light in weight and can be conveniently handled even if they need to be carried from one location to another.

Product Innovation is Acrylic Sheets Production

Ongoing evolution is all courtesy to innovation in acrylic sheet production. As the years have gone by, a number of advanced techniques were developed further to improve the quality and performance of acrylic sheets. Advanced technologies like digital printing, laser cutting and thermoforming have transformed the creation of custom designs in acrylic sheets without compromising on quality.

When compared to other materials, acrylic sheets excel in safety. Acrylic properties allow it to handle shatter impact nicely and quite differently from glass, which is much more prone to breaking in dangerous shards. In addition, acrylic sheets are considered safe for use in food applications because they do not react with foods or beverages and will not compromise product taste.

Acrylic Sheet Used for Variety of Applications

Acrylic sheets are remarkable in that they can be used for many different applications due to their highly versatile nature. Their versatility can be seen in signs, exhibits and furniture where these sheets are used for manufacturing. Given its easy manipulation to meet the specific needs of products, acrylic provides an ideal solution for crafted display cases and stands. Acrylic sheets are widely used in the construction sector, for example as windows, skylights and canopies testifying to its versatility.

How to work with Acrylic sheet

Acrylic sheets are easy to use and handle. An acrylic sheet can be cut by scoring it with a sharp metal and then bending the pane into two along the scored line. Another option for dividing the material is a circular saw or jigsaw. Use a fine-toothed blade if you want to avoid ragged edges and sand the cuts afterwards smooth.

Quality service plays a critical role in acrylic sheets. It is very important to choose a good or reliable supplier who has no defects in the sheets because an incident like this provides perfect end product. Also, authorized dealers provide good customer care with after sales support and service as well which further enhances the entire user experience.

Acrylic sheet is commonly used in commercial and residential settings. In industrial sectors, these sheets are used for preparing signs, shows and company logos in order to develop an unique image of the brand. In residential situations, acrylic sheets instead operate as windows (double-glazing) skylights and roof coverings to name but a few.

Thus, as an alternative for glass, acrylic sheets present themselves excellent. The advancement of technology in the production of acrylic sheets guarantees their resilience and appropriateness for different needs. We offer them some of the best and safeties, longevity this is why they are available of top-of-mind choice in various projects. When you chose acrylic sheets, it must be from a reliable supplier to provide good quality of products and customer service with B2B(primary) price.

Outdoor anti-UV acrylic panel colors change slightly but it will not fade after 30 years Our acrylic panels comply with industry standards and country standards We offer a 30-year guarantee for color changes in acrylic panels We promise that the colour of acrylic panels will not change significantly over the warranty time and that there will be no obvious yellowing or discoloration

Our team of experts has more than 20 years of experience in the industry and can quickly respond to customer requests. It doesn't matter if you're a professional contractor or an Acrylic sheet our sales representatives can always have a good contact with you. Likewise, our design team members can provide scheme proposal drawings quickly. We'll try our best to take care of urgent projects and deliver them on time.

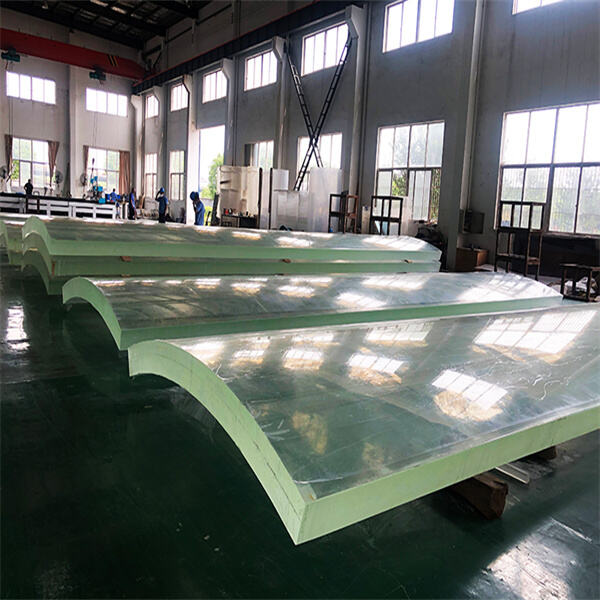

100% pure MMA Imported from Mitsubishi Lucite, acrylic panel transmittance of more than 93 percent. CNC cutting brings more precise dimensions. Each panel features a perfect, smooth surface. More seam strength (if there is any) After splicing, the panel is annealed to give better strength and aesthetics. Annealing removes stress of acrylic panels tempered in oven. We conduct a thorough inspections under lights for each panel before packing. To exceed the Acrylic sheet expectations We pay close attention to every aspect of the manufacturing process.

Acrylic sheet provides a complete solution that includes aquarium design, fabrication of acrylic materials, LSS equipment, installation, and commissioning. With our experienced design team, we are able to create public aquarium plans as well as development as well as construction design. Our factory produces thick acrylic panels (40-800mm) that are used for windows and tunnels for the oceanarium. We design life-support systems for aquariums with large sizes, and also provide equipment at affordable costs. If necessary, our staff can install on-site all around the world.