When looking for a versatile and durable material to use in your house, school or work project? But what about clear acrylic sheets so without any further a do- These Products clear plastic sheets provide a wealth of benefits and can be used in many applications. Today, we will further into the lovely diverse realm of clear acrylic sheets and everything they offer you including its pros as well where to get them with all ease or comfort.

There are a number of reasons why the clear acrylic sheets outshines traditional glass.

The material is lighter - Acrylic sheet weighs half as much as glass pieces do, which makes it far easier to lift and carry. And due to their shattered proof nature, they do not break into sharp edges pieces when hit. UV-protection & Weather-Resistant - This sheets can block most ultraviolet rays that may harm your skin or indoor and outdoor items. Furthermore, they are weather resistant and can withstand rain or snow as well as extreme temperatures. Common applications for these light diffusing acrylic plexiglass sheets include: fluctuating signs, outdoor and indoor use and greenhouses or skylights.

Easy to Shape and Customize According To the Desired Size or aquarium acrylic sheets FormThe clear acrylic sheets can be easily re-sculpted, which means they could cut intertwined drilled bent output engraved of glued and result in any designed pattern. These can be used to include colors, textures or prints and have the potential of offering shades with light diffusing properties.

Filling in the Gaps - Acrylic sheets are significantly cheaper to purchase comparing to glass, providing an all-round benefit for small businesses and homeowners equally. They are also environmentally-friendly, as they can be entirely recycled and consume less energy for manufacturing than glass.

As a user, clearly acrylic sheets are very friendly. The following tutorial will explain how to use them :

Start by measuring the required size and style of an acrylic sheet for your project.

Moreover, clamp the sheet on a flat as well stable surface.

Using a saw, drill or cutter make shallow groove (or score) along the marked line on the sheet.

Carefully bend the sheet along the score perforated line for a clean break in your forming process.

Wipe the sheet surface with a soft soap solution or alcohol-based cleaner.

You can then install or place the acrylic sheet wherever it is needed on your project for an aesthetic and practical touch.

The clear acrylic sheets come in various grades, with varying thicknesses to meet different requirements and quality levels. Depending on the level of security you need, select from standard to impact-resistant or bullet-resistant grades. Moreover, there are choices like anti-glare/anti-static treatment coatings and a flame-retardant feature or food-grade certifications. All these above-mentioned additional and extras are provided by most of the supplier offering services in plexiglass at Perth.

To sum it up, the clear acrylic sheets emerge as an outstanding option for all those who are looking forward to have a surge-resistant yet affordable material in hand. These benefits include a variety of applications previously not possible with glass and multiple safety, utility, protective options that can raise your production levels helping you to perform better or just simply live-protected; acrylic sheets simplify the versatile value-added tasks through endless projects in all industries sectors.

Outdoor anti-UV acrylic panel colors change slightly with age but not fading after 30 years Our acrylic panels are in compliance with industry standards as well as country standards We offer a 30-year guarantee on changes in color of acrylic panels We guarantee that the colors of acrylic panels won't change significantly during the warranty time and that there aren't any visible signs of yellowing or discoloration

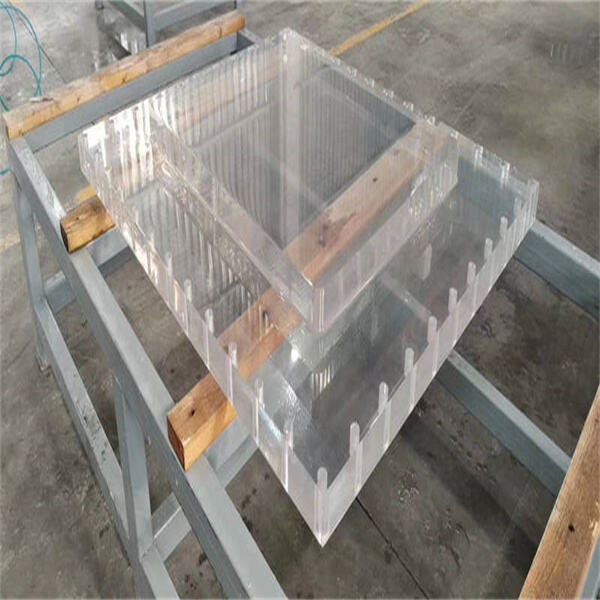

100% purity MMA imported from Mitsubishi Lucite, acrylic panel transmittance of more than 93%. CNC cutting brings more precise dimensions. Each panel is Clear acrylic sheet polished with a smooth surface. If needed, stronger seam strength is achieved After splicing, panels are annealed for better strength and aesthetics. The stress inside acrylic panels that are tempered is removed through annealing. We ensure that we conduct an exact examination under light for each panel before packing. We pay attention to every aspect throughout the process of manufacturing to exceed the customer's expectations.

Our team of experts has more than 20 years of experience in the industry and can quickly respond to customer requests. It doesn't matter if you're a professional contractor or an Clear acrylic sheet our sales representatives can always have a good contact with you. Likewise, our design team members can provide scheme proposal drawings quickly. We'll try our best to take care of urgent projects and deliver them on time.

Lanhu can provide turnkey solution including aquarium design as well as Clear acrylic sheet LSS equipment supply, and onsite installation and commissioning. We have a design staff which can offer public aquarium development, planning, and design concepts for construction. Our factory manufactures thick acrylic panels(40-800mm) for oceanarium windows and tunnels. We are able to design life support systems for aquariums with large sizes, and provide equipment at competitive cost. If necessary, our experts can install on-site all around the world.