How was the giant acrylic tunnel in the aquarium constructed?

The material is crucial. Ordinary glass cannot withstand the immense pressure of thousands of tons of seawater, so acrylic is the material of choice due to its high strength and exceptional transparency. Not only does it have a light transmittance exceeding 92%, it also possesses extremely strong impact resistance, more than ten more times that of glass. More importantly, acrylic can be heat-bent into curved panels, creating the curve shape of the tunnel.

Splicing process. A giant tunnel cannot be constructed from a single piece of acrylic; instead, it is constructed by splicing multiple acrylic boards with a thickness of tens of centimeters together. Workers use a special transparent adhesive to seamlessly bond the panels, then polish them to make the joints virtually invisible. This technique ensures the tunnel's overall strength and aesthetic appeal.

During the construction phase, the curved tunnel structure is typically prefabricated on land and then lifted as a whole to the designated location. Water is then gradually filled in for pressure testing to ensure the tunnel will not deform or leak due to the water pressure.

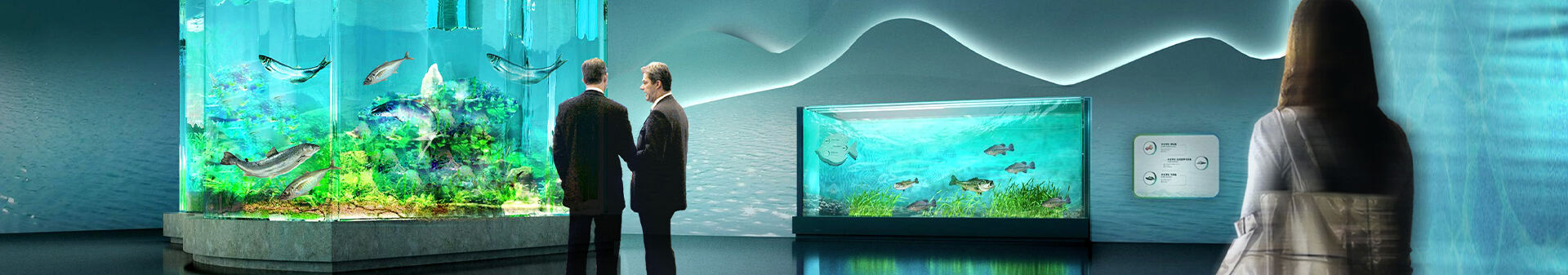

More and more aquariums, complexes, and resort hotels are turning to professional teams to design and install giant acrylic aquariums and tunnels. Shanghai Lanhu Aquarium Engineering specializes in large acrylic aquarium and installation. Leveraging their experience and expertise, they create safe, stunning, and artistic ‘underwater worlds’ for their clients.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

UK

UK

VI

VI

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS