An acrylic sheet is a type of special plastic material that comes in multiple colors, thicknesses and can be used for many things. They are flexible and easy to mould. This acrylic sheet blog will take you through several advantages of custom printed acrylic sheets and promote the role of innovation, safety, quality, application type and service in-application for sheet sector.

Acrylic Sheets: What make some of its types excellent for optical clarity is their good see-through abilities allowing light to pass through with little distortion. The high transmittance of UVC arms is well suited to applications requiring clear visibility, for example in museum displays or retail showcases and signage. Additionally, they are UV resistant which makes them great for outdoor use. Acrylic lends less risk of breakage, as they are not shatterproof like conventional glass. Moreover, they are lightweight when in comparison to bulky and fragile glass alternatives which lead to extent comfort of handling, transporting and installing both.

It is essential to customize acrylic sheets are therefore, two of the main pillars in maintaining sustainability and innovation. Thus, manufacturers continue to look for new ways in which they can improve the strength, durability and flexibility of acrylic sheets. At the same time, they are researching new colors and textures to better serve their customers. They also adhere to the strictest standards with regards to safety, undergoing intense testing for flammability and fire resistance as well as being free from harmful chemicals.

Custom Acrylic Sheets and Their Tactical Use Cases

These products have a variety of uses from keeping concrete plexiglas acrylic sheet simple to being used as furniture, decor features and consumer goods. They are used for a variety of purposes such as window replacements, skylights and sound barriers in buildings; protective pieces to protect machine operators from flying debris in manufacturing settings. Acrylic sheets are used in cars for tail lights and other elements of the vehicle as well. In the consumer realm, they are used as aquariums and furniture pieces or home decor elements.

Product quality, and service from manufacturers are essential factors in the differentiation of acrylic sheet products. Raw materials and manufacturing processes determine the durability, uses, and functionality of these metal sheets. Manufacturers adhere to strict quality standards in order to meet the satisfaction of customers. Moreover, they provide a variety of services including tailored applications solutions and full service customization as well as fabrication/installation. Such services include cutting, laser engraving, thermal forming and many more.

With a variety of impressive attributes like great optical clarity, UV resistance, shatterproof features and ease in handling/accomplishing installations; customized acrylic sheets are the way to go. This continued focus on innovation and safety highlights the dedication of manufacturers to constantly better themselves. Thanks clear acrylic sheet to all of the convenient properties including chemical resistance, UV / weathering resistance and others acrylic sheets have become irreplaceable in industries like construction or automotive. When the manufacturer is chosen carefully, then they would easily get world class products and also customize services appropriately as needed by them.

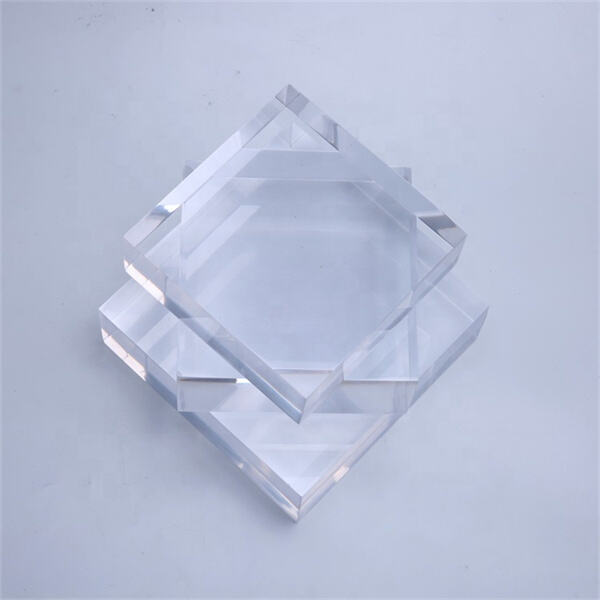

Customize acrylic sheet of acrylic panels is more than 93 percent. 100% purity MMA obtained directly from Mitsubishi Lucite. CNC cutting brings more precise dimensions. Each panel is perfectly polished with a smooth surface. If needed, stronger the strength of seams After splicing, the panels are annealed for better strength and aesthetics. Annealing removes stress on acrylic panels when they are and can be tempered in oven. We perform a rigorous check under lighting for each panel prior to packing. We pay attention to every aspect throughout the process of manufacturing to exceed the customer's expectations.

Our Customize acrylic sheet has over 20 years of industrial experience and can be responsive to customer requests. Our sales representatives can maintain excellent communication with the end user or contractors, while our design teams can rapidly give drawings of scheme proposals. We'll do our best to meet the demands of your urgent project and ensure they are completed in a timely manner.

Lanhu can provide turnkey solution including aquarium design as well as Customize acrylic sheet LSS equipment supply, and onsite installation and commissioning. We have a design staff which can offer public aquarium development, planning, and design concepts for construction. Our factory manufactures thick acrylic panels(40-800mm) for oceanarium windows and tunnels. We are able to design life support systems for aquariums with large sizes, and provide equipment at competitive cost. If necessary, our experts can install on-site all around the world.

Outdoor anti-UV acrylic panel colors change slightly but it will not fade after 30 years Our acrylic panels comply with industry standards and country standards We offer a 30-year guarantee for color changes in acrylic panels We promise that the colour of acrylic panels will not change significantly over the warranty time and that there will be no obvious yellowing or discoloration