So, first of all, the manufacturers are casting acrylic sheet. They manufacture clear plastic sheeting, which is frequently used in windows, signs and even aquaria. Shanghai Lanhu is one of the most famous companies that manufacture these sheets. They are specialists in the manufacture of robust acrylic sheets.

But do you ever wonder, how these sheets are produced? But at the beginning, you have a thing called methyl methacrylate which is a liquid. This raw material is poured into a mold and then heated until it forms a solid sheet. This process is called polymerization and this is how the acrylic sheets achieve their strength and clarity. The slice for whatever it will be used is finally put on the shape and form of the sheet once it has cooled down.

Having the right equipment and technology is one of the greatest secrets that successful manufacturers keep. For instance, Shanghai Lanhu utilizes high technology equipment to ensure they make their acrylic sheet right the first time. The other secret is having an experienced team of people who can use the materials to create a sheet following all the steps in order to achieve the high qualities.

There are a few factors, when looking for an acrylic sheets company that can manufacture it for your project. The first—ensure the manufacturer is known for producing quality sheets. If you want to find out how good these shoes actually are, simply go through customer reviews or ask for some samples yourself. Take into account the sort of expertise and experience with the manufacturing of automobile gearboxes. For example, Shanghai Lanhu has been producing cast acrylic sheet for many years and is good at it.

Acrylic sheets are a costly investment therefore producing them will be extremely challenging. This guarantees that each sheet is personally inspected for error or imperfection and only afterward dispatched for sale. Shanghai Lanhu has a very strict requirement for quality control to produce every slab which was leave factory flawless. And since they work with such detail, you can rely on B+W to produce the best in existence.

The acrylic sheet business is one that is constantly in flux with new innovations and technologies being created all the time. Shanghai Lanhu is at the forefront of these developments, constantly looking for ways that they can improve their manufacturing process so they can produce even higher-quality sheets. One such instance is by incorporating recycled materials into their sheets to prevent waste and lessen the environmental impact on the earth. Shanghai Lanhu has been keeping pace in leading the industry, providing their clients with good cast acrylic sheet clear with them being one step ahead.

Our team is comprised of more than 20 years of industrial experience and can Cast acrylic sheet manufacturers quickly to customer requests. Our sales team has excellent communication with the end user or contractors, while our design teams can rapidly draw up schemes. If you have a project that is urgent We do to be flexible in management and timely delivery. With extensive experience, we can always guide the client to find the best solution.

Outdoor anti-UV acrylic panel color change a little and will not yellow after 30 years Our acrylic panels comply with international standards and standards We offer a 30 year guarantee on color changing We promise that the colors of acrylic panels will not be significantly altered during the warranty period and there will be no obvious discoloration or yellowing

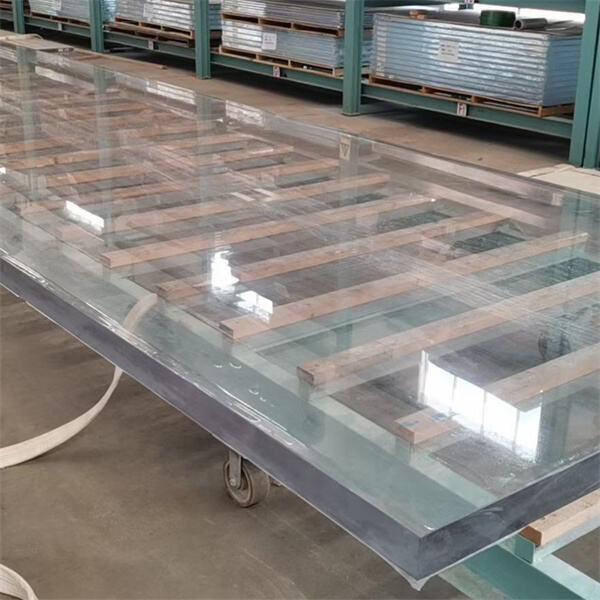

100% pure MMA imported from Mitsubishi Lucite, acrylic panel transmittance greater than 93%. CNC cutting brings more precise dimensions. Every panel has a flawless, polished surface. Better seam strength (if there is one): Cast acrylic sheet manufacturers after splicing to give better quality and aesthetics. The stress inside acrylic panels that have been tempering can be eliminated by annealing. We ensure that we conduct an exact inspection under lighting for every panel prior to packing. To meet or exceed the expectations of our clients, we pay attention to every aspect of production.

Lanhu offers turnkey solutions from aquariums design and fabrication of acrylic materials, LSS equipment, Cast acrylic sheet manufacturers and commissioning. Our design team is comprised of experts that is able to provide public aquarium development, planning, and design concepts for construction. Our factory manufactures strong acrylic panels(40-800mm) to be used as oceanarium windows and tunnels. We design life-support systems for large aquariums, and provide equipment at competitive prices. If required, our technicians can perform installation on site all around the world.